How does Food Irradiation work?

Food is exposed to a carefully measured amount of intense ionizing radiation. This is done in a special processing room or chamber for a specified duration. With food irradiation, radiant energy (electrons, gamma rays, or x-rays) breaks chemical bonds, leaving the food still like-fresh, but with specific benefits, depending on treatment level.

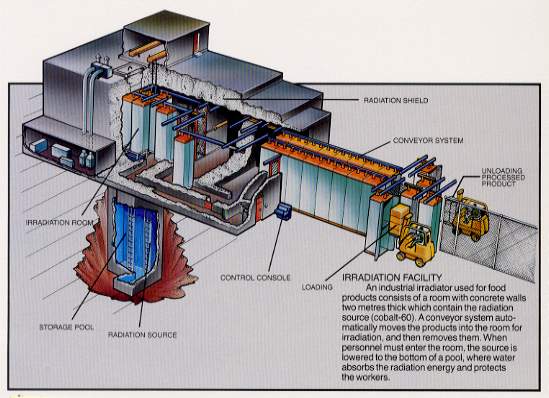

- Irradiation Room: When the cobalt is in the water, people can safely enter the irradiation room.

- Radiation Source: Cobalt is shielded under water in an underground tank when not in use.

- Control Console: Treatment is controlled by the speed of the conveyer belt. Amount of energy needed varies by the density of the load.

- Loading: Packaged food is loaded onto a conveyer belt for treatment.

- Unloading Processed Product: Treated food can be handled immediately. The fence keeps treated and untreated food separate.

- Radiation Shield: Concrete walls prevent gamma rays from escaping into the environment.

Types of Facilities

Cobalt 60, Gamma Facility

The most common source of ionizing energy is cobalt 60. This radioactive material is contained in two sealed stainless steel tubes (one inside the other - double encapsulated) called "source pencils." These are placed in a rack and the entire rack is immersed in a water chamber underground when not in use. When irradiation takes place, the rack is raised. Packaged food products move along the conveyer belt and enter an inner room where they are exposed to the rack containing source pencils. Energy in the form of gamma rays (or photons) pass through the encapsulation and treat the food.

The most common source of ionizing energy is cobalt 60. This radioactive material is contained in two sealed stainless steel tubes (one inside the other - double encapsulated) called "source pencils." These are placed in a rack and the entire rack is immersed in a water chamber underground when not in use. When irradiation takes place, the rack is raised. Packaged food products move along the conveyer belt and enter an inner room where they are exposed to the rack containing source pencils. Energy in the form of gamma rays (or photons) pass through the encapsulation and treat the food.

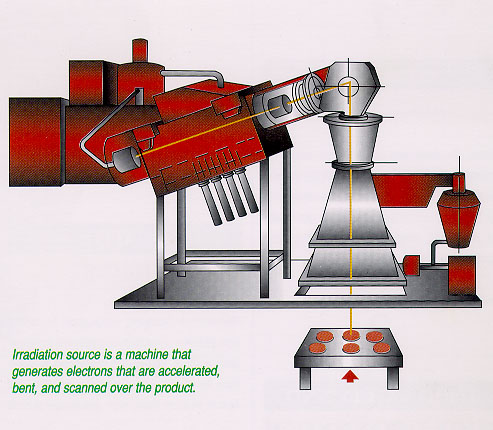

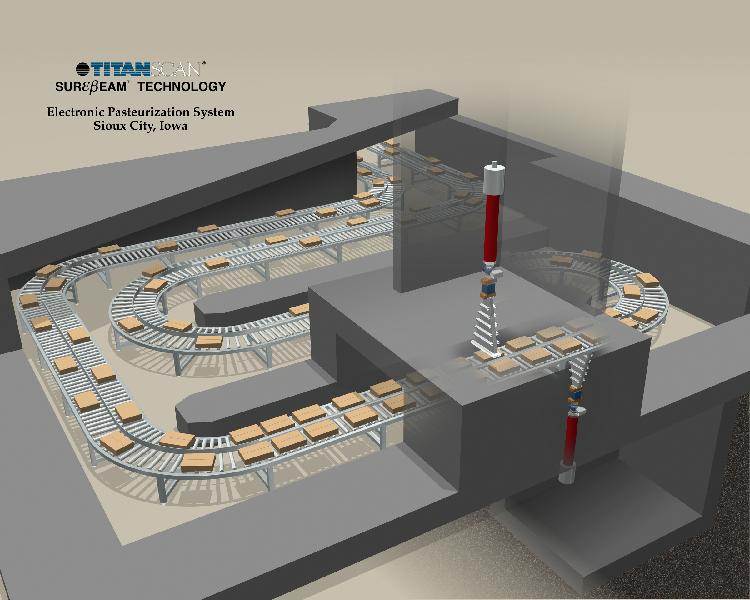

Electronic Beam Facility (E-Beam)

The Electron Beam Linear Accelerator, (E-beam) Accelerators work on the same principle as a television tube. Instead of being widely dispersed and hitting a phosphorescent screen at low energy levels, the electrons are concentrated and accelerated to 99% of the speed of light. This produces rapid reactions on the molecules within the product. The Electron Beam Linear Accelerator machine generates and accelerates electrons to energies of 5,7.5 or 10 MeV (Million electron volts) with beam power of up to 10 kW.

A Conveyer or cart system moves the product to be irradiated under the electron beam at a predetermined speed to obtain the desired dosage. Products move in and out of the irradiation area continuously. Product thickness depends on density and electron energy. For example, e-beam energy can penetrate meat a total of 3.5 inches with treatment on the top and bottom of a package.

X-Ray Facility

Food can also be irradiated by X-rays. In this sytem an electron beam accelerator targets electrons on a metal plate. Some energy is absorbed and the rest is converted to X-rays. Like gamma rays, X-rays can penetrate food boxes up to 15 inches thick or more, thus permitting food to be processed in a shipping container.

When food is irradiated, most of the radiation passes through the food without being absorbed. The small amount that is absorbed destroys any insects on grains,produce or spices, extends shelf life, and prevents fruits and vegetables from ripening too fast. Thus, food irradiation may replace chemical fumigants, sprout inhibitors, and post harvest fungicides. Higher doses can kill Salmonella and other harmful bacteria that can contaminate meats and poultry and cause food borne diseases.

Food irradiation is a "cold treatment" that achieves its effects without raising the food's temperature significantly, leaving the food closer to its original state. Even spices which are treated for 2-4 hours remain essentially at room temperature. By not using high temperatures, food irradiation minimizes nutrient losses and changes in food texture, color, and flavor.

The energy used in food irradiation is not great enough to cause food to become radioactive. During irradiation, energy passes through food much like a ray of light passes through a window. This energy destroys most of the bacteria that can cause disease, yet allows food to retain its high quality.

Irradiation pasteurizes food by using energy, just as milk is pasteurized using heat. At the level used, most harmful bacteria will be destroyed. Afterwards, surviving bacteria could start to multiply if the food were mishandled: such as, stored at an improper temperature. The level of irradiation used also does not kill certain spoilage organisms. This is for the protection of consumers. Spoilage bacteria will multiply and alert consumers not to use a product which has been improperly handled.

As with any food, consumers must take appropriate precautions, such as refrigeration and proper handling and cooking to make sure that potentially harmful organisms do not multiply.

Facility Safety

Water is used to shield the cobalt when it is not in use. The water is not radioactive.

Water is used to shield the cobalt when it is not in use. The water is not radioactive.

Irradiation facilities must include many safety features to prevent both environmental and worker exposure. The use and transportation of radioactive materials - including the equipment and the facilities in which they are used -- are closely monitored by the Nuclear Regulatory Commission, state agencies, and the Department of Transportation.

A food irradiation plant is not a nuclear reactor. In a reactor, a nuclear chain reaction takes place, heat is generated and used to make steam which turns a turbine and creates electricity. Proper controls are needed to contain the chain reaction and maintain proper cooling. A food irradiator is completely different.

The effects of treatment by e-beam, cobalt 60, cesium 137 are identical. Use of one method or another is based upon product size, facility size, anticipated throughput, and other factors.

The effects of treatment by e-beam, cobalt 60, cesium 137 are identical. Use of one method or another is based upon product size, facility size, anticipated throughput, and other factors.